The hum of our modern world is increasingly powered by clean energy, a transition made possible by the quiet revolution of energy storage. These massive battery systems are essential for balancing the intermittent nature of renewables like solar and wind, playing a vital role in creating a sustainable future. But with this rapid growth comes a critical challenge: ensuring safety. The sheer scale of these systems, the complex chemistry involved, and the vital role they play in our energy infrastructure demand nothing less than the highest safety standards.

Energy storage is the backbone of the clean energy transition, providing the flexibility needed to integrate more renewable energy onto the grid. Safety must remain a top priority as storage scales rapidly to ensure the industry keeps the public’s trust. There is little room for error. Any missteps set the industry back and slow the advancement of new technologies.

High-profile incidents, such as the Moss Landing fire in Monterey County, California this January, have shaped how the industry approaches fire safety. The cause of the fire remains under investigation at the 750 MW/3,000 MWh facility that burned 100,000 lithium-ion batteries. The flames that engulfed a section of the facility served as a stark reminder of the potential risks inherent in this technology.

The industry can ensure the reliability of energy storage technology by learning from past incidents and continuing to prioritize safety.

Safety Advancements Since Moss Landing Became Operational

The energy storage industry has made major strides in enhancing safety, with an ongoing focus on advancements in battery chemistry, facility design, and monitoring systems to mitigate fire risks. One key development has been the widespread shift from nickel manganese cobalt (NMC) batteries to lithium iron phosphate (LFP) chemistry. LFP batteries are inherently more stable and less prone to thermal runaway—the uncontrollable chain reaction that can lead to fires.

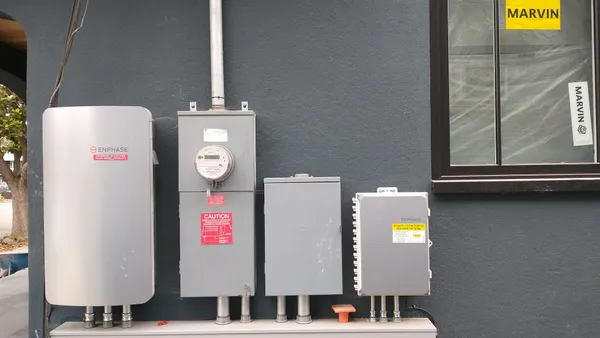

But the progress doesn’t stop at battery chemistry. The very architecture of energy storage facilities has also evolved to mitigate fire risks. Instead of grouping hundreds or thousands of battery racks inside enclosed buildings, the industry has moved toward modular, outdoor enclosures. This design houses smaller quantities of batteries within multiple weatherproof containers, with adequate spacing between enclosures to effectively limit the potential for fire spread. These modular containers undergo rigorous compliance testing and review, further enhancing their practicality.

Beyond the changes in battery chemistry and physical design, monitoring and control systems to detect anomalies and prevent fires before they start have also advanced considerably. Voltage, temperature, and current anomalies can be detected through streamlined communication between each module’s battery management system (BMS) and sophisticated battery analytics software. Once an anomaly is detected by the software, it alerts operators to the most critical anomalies that could lead to fire risk, enabling the operator to act quickly to disconnect or service the battery before an incident could ever occur. For example, the battery analytics software may detect that a battery string's temperature is consistently rising over a week and alert the system operator before the issue turns into a potential safety issue.

New Safety Recommendations for BESS Facilities

The energy storage industry has been working closely with state and local agencies to address concerns raised by the Moss Landing incident and promote safety at all energy storage sites. Newer projects using containerized design inherently limit the scope of potential fires by restraining them to the scale of one container. Even still, the implementation of rigorous safety measures at all future energy storage facilities is needed.

Organizations like the California Energy Storage Alliance (CESA) and American Clean Power (ACP) are championing these efforts, pushing for advancements in safety protocols for both new and existing facilities. These standards encompass everything from site selection and hazard assessment to emergency response planning and personnel training.

Despite the visibility of recent incidents, BESS fires are extremely rare. Continued improvements in technology and regulation are making such incidents even less likely. While the Moss Landing fire involved a significant number of battery modules, air, soil, and water quality analyses conducted by state and federal officials found no contamination that would put the local community at risk—demonstrating that the impacts of energy storage fires are comparable to other structural fires.

Industry Leadership: The Key to Continued Safety

The energy storage sector shows no signs of slowing down; therefore, industry leaders must remain vigilant in implementing and advocating for best-in-class fire safety practices. This includes advancing safer battery chemistries, smarter site design, and supporting the adoption of rigorous testing and modeling standards and fire codes. The industry has been proactive in helping to shape regulations, not just follow them. In many cases, manufacturers and project developers have adopted best practices, for example subjecting energy storage projects to large-scale fire testing, before regulations mandated them.

We can ensure BESS remains not only a foundational technology for decarbonizing the grid but also one that meets the highest standards if we learn from past incidents and push for continued improvements.

This isn’t just about preventing another Moss Landing. It’s about building public trust in a technology that’s essential for our clean energy future. By prioritizing safety, fostering transparency, and embracing continuous improvement, the energy storage industry is not just powering our homes and businesses—it’s building a foundation for a sustainable and secure tomorrow.