The science of engineering appeals to me for many reasons. I like to solve problems. I like to create. I like to look at the half-full glass and wonder if a smaller glass would be more efficient.

I’m not as interested in counting things.

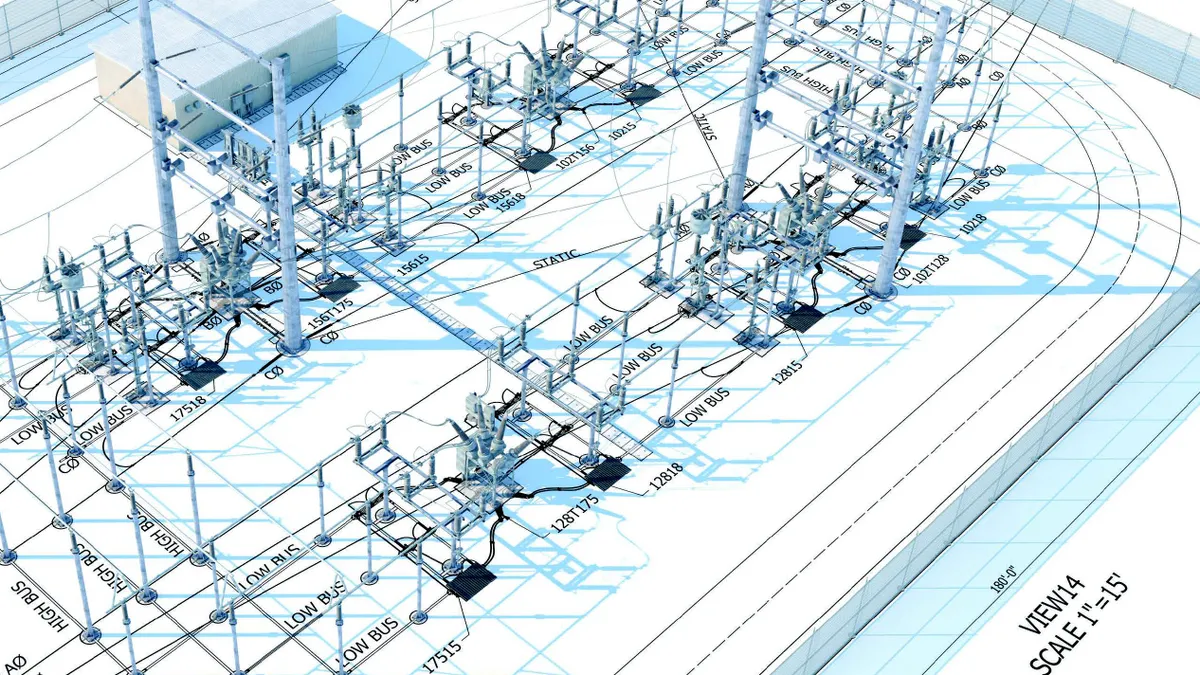

I realized this early in my career. Three or four years after I graduated with my engineering degree, one of the first tasks I was given at Duke Energy was to count the nuts, bolts and washers in the design we just completed for a new substation. They handed me a stack of drawings and said, “Here.”

I was thinking to myself, “I’m a professional engineer, right? I finished my degree and I'm engineer. And I'm counting nuts, bolts and washers to make sure that we have the right numbers going into the field.”

I was also thinking, “This is not the way to go.” So, I attended a 3D modeling class for Autodesk’s Inventor design software. And the eureka moment happened. Use the program, put the information into the model and it automatically updates your building materials. No more counting nuts, bolts and washers.

That moment lit the fire that has powered my career for decades in engineering design. Understanding the software led me to work with others at Duke to develop specifications and processes to help people design the utility assets and rebuilds that we needed. We were successful transforming our robust, existing standards into intelligent modeling.

Over the years, my former team and other utility engineers kept pace with the technology as it evolved. Together we developed the Substation Design Suite software in conjunction with Autodesk and Automation Force. We also formed a community called the Substation Design Solution Industry Consortium (SDSIC), made up of member utilities and contract design and engineering firms who have adopted, or are investigating for adoption, leading technology software platforms along with those software developers.

The consortium establishes common workflows and toolkit functionality, shares libraries and standards, and discusses technology needs and other topics that help drive vendors to software development according to an industry standard. Our motto, “design, integrate, automate,” reflects our commitment to drive standards to promote common library development from internal resources, external partners, and/or equipment manufacturers.

Thanks to the SDSIC and BIM users around the world, the technology I’d been eager to learn about years ago has become so much more than just a means to eliminate repetitive design tasks. Utilities now implement processes based on a single source of accurate information, connected to an intelligent 3D digital model that everyone in their organizations can use to get their jobs done, wherever they are in the process.

Yet despite all these advancements that BIM provides in efficiency and accuracy, many substation engineers are still using 2D tools for design. There are some stubborn barriers to adopting this technology. For BIM champions seeking to bring their organizations’ design operations forward, the struggle is real.

Objections that BIM champions often face include:

- Is BIM worth it?

- How are we going to pay for it?

- How do we teach staff to use new technology while doing their “day jobs?”

I feel so strongly about the value of intelligent design that I worked with some BIM subject matter experts to write a guide to help utility staff persuade decision makers. It’s called the “Convince Your Boss” Toolkit. If you are looking for evidence to help justify and advance a BIM transition at your utility, download our eBook. If you are facing a concern the guide hasn’t addressed, let’s connect. I’d be glad to help. You can contact me at [email protected]