Much has been written about the shifting landscape of the modern-day utility industry. Once considered one of the more conservative and steadfast industries in the economy, today's utilities are faced by everything from an influx of distributed energy resources (DER), bi-directional power flows, regulatory mandates requiring the attainment of ambitious clean energy goals, and the emergence of sensors and digital tools capable of improving operations and planning.

However, it's important to recognize what hasn't changed. Utilities are still expected to deliver safe, reliable, affordable, and increasingly clean energy to the millions of residential and commercial customers who depend on it—all while remaining compliant with the many regulations that govern the industry.

"Utilities are highly regulated and held to high standards to deliver safe, reliable, and resilient services," said Teresa Elliott, Bentley Systems' Industry Marketing Director for Utilities & Digital Cities. Though it's difficult to catalogue all the regulations utilities must comply with, some of the more important ones include worker safety mandates overseen by the United States Department of Labor's Occupational Safety and Health Administration (OSHA), the North American Electric Reliability Corporation's (NERC) Critical Infrastructure Protection (CIP) standards related to cybersecurity, and the United States Environmental Protection Agency's (EPA) National Emissions Standards for Hazardous Air Pollutants (NESHAP) that regulates the emissions of hazardous air pollutants.

From the time utility assets are commissioned to the actual operation of the infrastructure, there are numerous regulatory reviews and audits. Adding to that challenge, agencies require an extensive amount of documents and data to ensure compliance with local and national regulatory mandates. Paperwork includes everything from legal documents to environmental impact analyses, construction drawings, and vegetation management plans.

"The list is almost endless," said Elliott. "To reduce the risk of fines and keep resources productive, teams need to access all the necessary information for both compliance reporting and for quick and definitive responses to audits."

Though it varies from utility to utility, achieving regulatory compliance can come with a significant price tag. In 2016, American Action Forum, a non-profit think tank, released a study revealing that the average nuclear power plant spends $8.6 million annually to comply with regulations. Nearly half of that amount, $4.2 million, was attributed to paperwork costs.

For that reason, regulators are starting to expect utilities to be going digital. Where before a scanned PDF of a signed inspection report may have been adequate, in some jurisdictions regulators are expecting individual inspection readings to be digital so they can be trended over time. In instances like this, the going digital strategy must also include the ability to automate the testing and inspection process. In California, for example, PG&E is implementing Bentley’s AssetWise software to automate the testing and inspection process to comply with recent state regulations. It's another step in the going digital strategy.

While the emergence of digital tools challenges the status quo, technology also provides an opportunity to significantly improve the speed and accuracy of compliance. "There is no single technology answer to solving the compliance issues a utility faces," said Elliott. "But an open, connected data environment creates the foundation necessary to access and use information for project delivery, asset operations and maintenance, and compliance."

One way to create an open and connected data environment that mitigates the time and cost of compliance is through the implementation of an advanced project management system. At a high level, a project management system becomes an organization's trusted source of truth, a place where engineers, operators, and other utility personnel can access necessary documents and data to demonstrate compliance but also have visibility around how they've changed over time.

The process required to set up a project management system positions a utility for streamlined compliance. "Not only can you instill company-defined standards, but you can adhere to compliance requirements by ensuring your teams produce the deliverables you expect and standardize how you store and access the information," said Elliott. "The system helps you enforce workflows that meet your compliance requirements, ensuring that the documentation and audit trails are in place for reporting or regulatory reviews. You can respond quickly, with the confidence that all your information is accurate, complete, and verifiable."

That simply isn't possible when a utility relies on what Elliott calls "dark" data, or information that exists only in paper records that haven't been digitized. When that is the case, utility personnel in different departments have to manually collect, enter, retrieve, and share data. When dark data is the norm, it has an impact on compliance, on operations and maintenance, and can even lead to expensive project work to replace and expand services in areas where there just isn't enough information about those buried assets.

"When someone needs to access information on buried assets, for instance, and those assets have been in the ground for 40-plus years, they likely have no digital record," said Elliott. "But there are engineering documents that include important information, such as welding thresholds or pressure tests. A utility needs to be able to access this information more easily and make it available to those who maintain those buried assets, for projects on or near those assets, and when there is an issue with that asset."

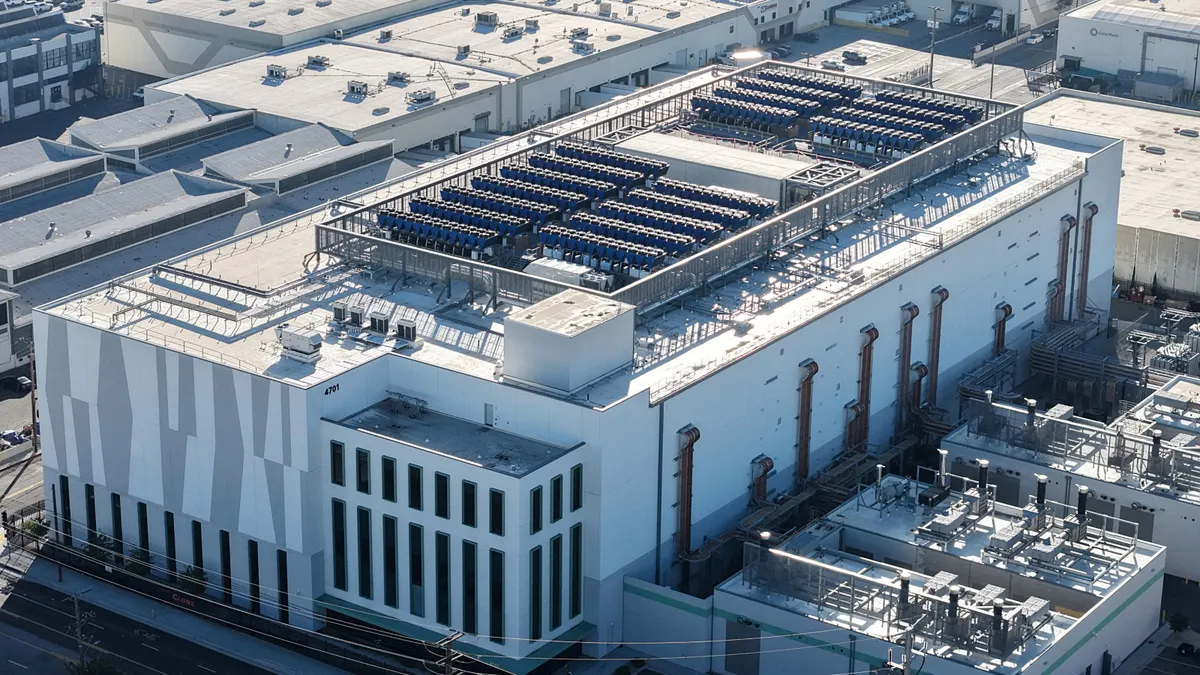

The experience of the Los Angeles Department of Water and Power (LADWP) illustrates the benefits of bringing light to dark data. LADWP is the largest municipal utility in the United States, serving 4.1 million citizens with 7,238 miles of water mains and 14,486 miles of electric transmission and distribution wires. Recently, LADWP undertook an initiative to improve their approach to project and document management.

LADWP chose ProjectWise to provide over 200 engineers, designers, drafters, and construction personnel fast and accurate reuse of 300,000 design and construction files. With the spatially enabled search interface, their users can select a region of interest and quickly discover all relevant drawings, pictures, and documents for assets in that area. ProjectWise has accelerated reference information research on new projects by 80% and has established lasting information by integrity and enforcing LADWP computer-aided design (CAD) and project standards.

Today, with tools such as Bentley Systems' ProjectWise companies can retrieve that information almost instantaneously. To learn more about ProjectWise and going digital, visit https://www.bentley.com/en/products/brands/projectwise.