Greg Matzat is market director for offshore wind and renewables at engineering consulting group COWI.

The Biden-Harris administration has set an ambitious target to deploy 15 GW of floating offshore wind by 2035 and become the global leader in that technology. Factoring in time to build the necessary manufacturing and port facilities to achieve this goal, as well as to secure permits and more, a back-of-the-envelope calculation shows the U.S. will need to deliver, on average, approximately one 20-MW turbine and the accompanying floating foundation every four days between the beginning of 2028 and the end of 2035.

It’s a scale of ambition that we’ve not seen in the U.S. since World War II.

A national effort

Between 1941 and 1945, 18 American shipyards built 2,751 Liberty ships, which measured 134 meters long with a lightship weight of around 4,000 metric tons. At the height of production in 1943, three ships were being finished every day. Over the course of production, the build time dropped considerably, from around 220 days per ship to just 39 days. All in all, it was a national effort of epic proportions.

The world’s largest prototype 15 MW turbine is not dissimilar in size to a Liberty ship, with a blade length of 118 meters and a hub height of approximately 148 meters. A semi-submersible floating foundation to support it could be up to 100 meters wide and weigh over 6,000 metric tons without ballast.

Achieving the administration’s floating offshore wind ambition would also require a national effort.

According to Offshore Renewable Energy, Catapult’s latest international market opportunities report for offshore wind, the U.S. is not only in a good position to achieve its domestic target, it could put itself in the running for the industry’s top spot, too. The report ranks the U.S. seventh in the world for its technical and socioeconomic readiness for floating offshore wind development, only a little behind countries such as the United Kingdom, South Korea, France, and Japan, which already have sizeable fixed-bottom portfolios as well as floating offshore wind demonstration projects.

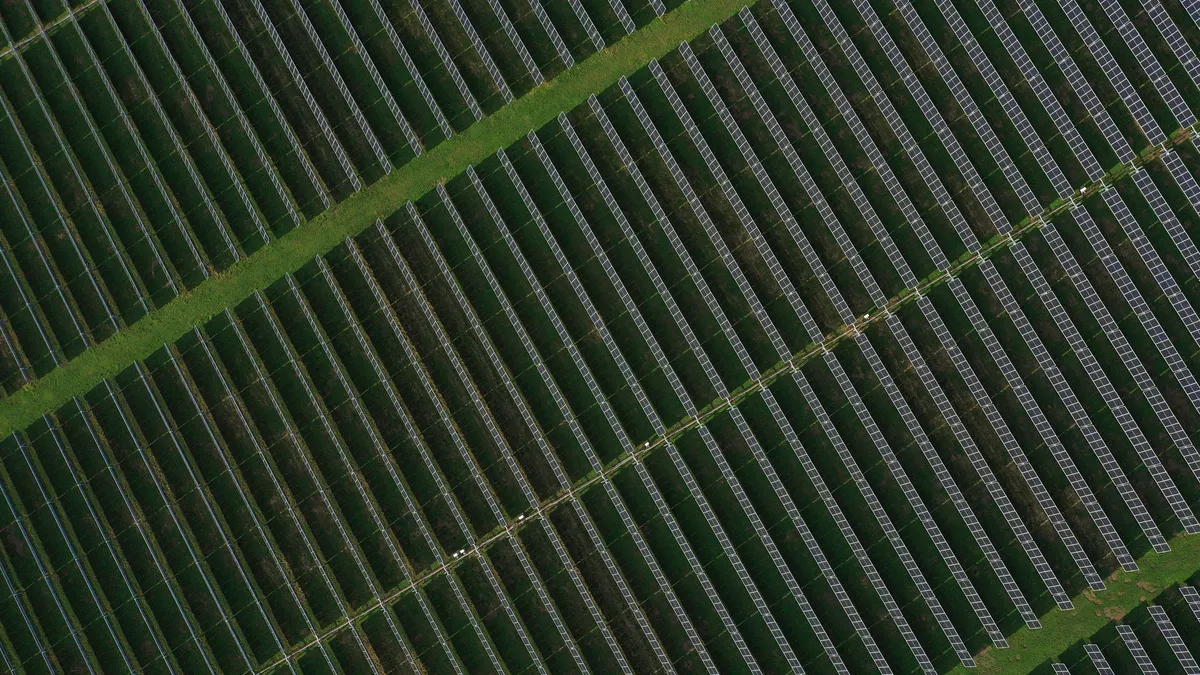

While the U.S. offshore wind industry remains in its infancy, developers remain undeterred, with 40 GW of projects in various stages of development. As this country’s vast onshore renewables industry has proven, it only takes a few projects to prove the concept and to smooth regulatory barriers before the market will naturally accelerate. In fact, the U.S. solar industry is now growing at such a rate that the Energy Information Administration expects solar power to provide nearly half of new U.S. electric generating capacity this year.

Swift acceleration needed

Swift acceleration from this point onwards will be absolutely vital if we are to achieve the Biden administration’s goal of becoming the global leader in floating offshore wind. We have a long way to go if we are to deploy a 20-MW floating wind turbine every four days! The construction of South Fork Wind — 12 11-MW, fixed-foundation turbines off the coast of Long Island, New York — commenced in February 2022, nearly a decade after the Bureau of Ocean Energy Management, or BOEM, auctioned the lease for the project. If the 15 GW-by-2035 target is to be met, we can’t wait 10 years after the first U.S. floating wind auction, held last week, to start deployments.

Although leasing is beginning to move faster, permitting is still a challenge, along with addressing where to bring the transmission cables ashore and interconnect with the existing electrical grid. While there are processes for leasing, permitting, transmission and interconnection, in order to achieve 15 GW by 2035, these processes will need to be more efficient. The most pertinent challenge, though, is building out the local supply chains and finding and constructing sufficient foundation fabrication, assembly, and turbine integration port facilities. While the U.S. Gulf Coast has ample offshore engineering and marine construction expertise as a result of oil and gas activities, and the West Coast has some very large shipping ports, the western seaboard currently lacks sufficient port capacity in terms of facilities for foundation fabrication, assembly and turbine integration to support the build-out rates required to meet Biden’s target.

To accommodate floating offshore wind, port facilities will need to be a minimum of 50 acres each, but preferably 75 to 100 acres or more of flat uplands. The facilities will need excellent transport links, deep drafts and high load-bearing capacity quays to accommodate the foundations as well as large transport vessels bringing in materials. The upland will need to be free of vertical restrictions such as bridges and be near additional large port facilities to support other stages of fabrication. And ideally, this all needs to be within about 250 nautical miles of the permitted sites for reasonable tows.

To construct floating offshore wind projects as quickly as possible, it would be best if port facilities could accommodate the construction of any of the three major foundation types — tension leg, spar and semi-submersible — as well as variations of each. This will require flexible port facility designs.

Of course, we don’t just need one or two ports as described, but several all along the West Coast to service prospective sites across California, Oregon, Washington and elsewhere in the U.S. Building the Liberty ships required 18 shipyards; for this challenge, we also will need multiple port facilities.

Federal, state and local investment are essential

At each facility, the necessary port upgrades will run to the hundreds of millions of dollars; this requires a major investment funded collaboratively from federal, state and private pots. The East Coast is already laying the groundwork for this, with ports such as the New Jersey Wind Port, South Brooklyn Marine Terminal in New York, and State Pier in Connecticut demonstrating how to finance these projects. The first phase of the New Jersey Wind Port, which is expected to be completed in 2024, was partially financed by the state and will cost about $400 million. As the nation’s first purpose-built offshore wind marshaling port, it is expected to create 1,000 long-term jobs and to support up to $500 million of new economic activity within the state and the region each year, all while supporting New Jersey’s commitment to the energy transition.

On the West Coast, the California Energy Commission recently issued a $10.5 million grant for a preliminary survey, impact assessment and design, engineering and early construction work with the view to establishing the Humboldt Bay Offshore Wind Heavy Lift Marine Terminal. This is a major victory for the industry, but we still need several more sites, and billions more dollars in investment, if the U.S. is to be in the running to become the world leader in floating offshore wind, as well as meet its domestic targets. It’s a matter of national effort.