Dive Brief:

- Tesla’s energy storage deployments decreased by 11% in the second quarter to 1.1 GWh, compared to the same period last year, predominantly because of challenges related to procuring semiconductors, the company reported Wednesday.

- Solar deployment, meanwhile, increased 25% year-over-year, touching 106 MW — the highest in four years, according to Tesla. Although the company is still facing delays in importing solar components, it has also expanded its supplier base.

- “The fundamental rate limiter for Earth transitioning to sustainable energy is how fast can you grow lithium-ion battery output per year,” Tesla CEO Elon Musk said on the company’s earnings call Wednesday. “[B]ecause you need the batteries for two of the pillars of sustainability — the stationary storage, and for vehicles.”

Dive Insight:

Like many other players in the energy sector, Tesla has been facing a variety of supply chain challenges over the last year, including the impacts of COVID-19 outbreaks on its factories, chip shortages, and the rising prices of raw materials.

Some of these problems persisted in the second quarter, and Tesla faced a variety of challenges related to COVID-19 shutdowns affecting its manufacturing, supply chain disruptions, labor shortages and other issues that prevented the company from operating its factories at full capacity. However, it also achieved record production rates for vehicle capacity during this period.

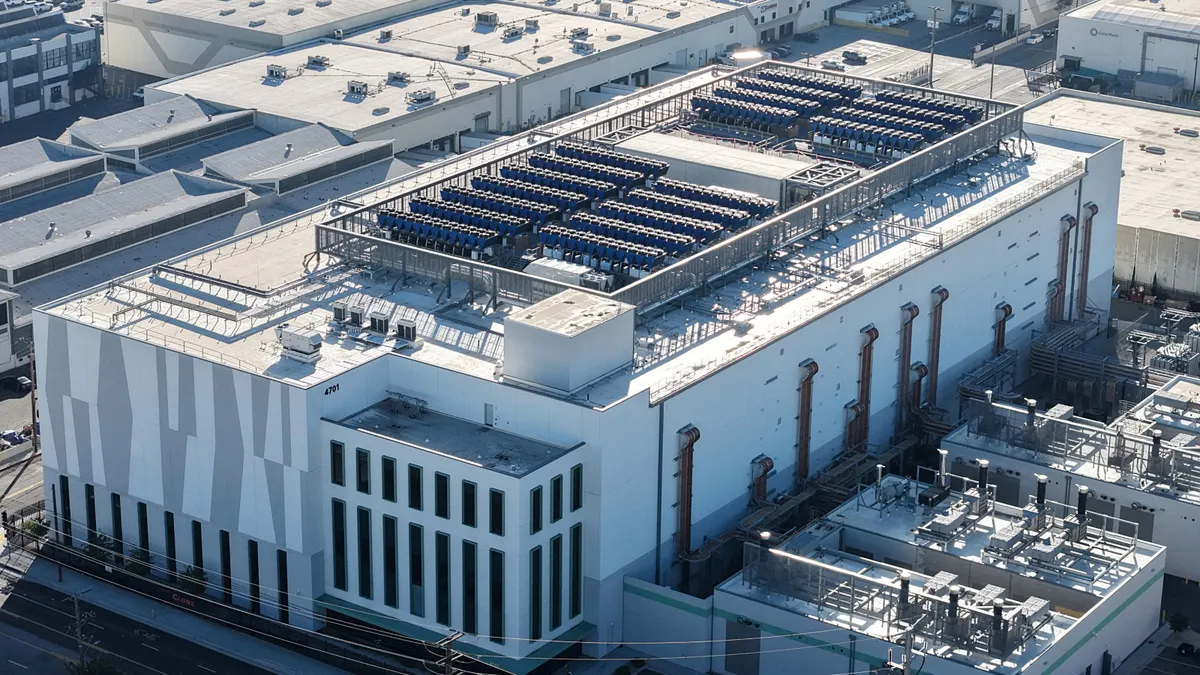

But while the company’s energy business “progressed well” in the second quarter, “our storage business remains component constrained on both Powerwall and Megapack, which we hope will alleviate to some extent in the second half of the year,” Zach Kirkhorn, Tesla’s chief financial officer, said during its earnings call.

One of the challenges the company has its eye on is constraints in refining the materials necessary to make lithium-ion batteries. While lithium is one of the most common elements on earth, the ability to refine it into battery-grade lithium hydroxide and lithium carbonate is quite difficult, requires a massive amount of machinery, and is hard to scale, Musk said on the call.

Musk reiterated his calls for entrepreneurs to enter the lithium refining business.

“It is basically like minting money right now — it’s like software margins in lithium processing right now,” he said.

Tesla is also making investments of its own in lithium refining and cathode manufacturing, Kirkhorn added.

“[T]he best way to learn how to accelerate something is to do it yourself. So these are the things we’re doing to move it all forward,” he said.