Dive Brief:

-

If it comes online as scheduled by year end, the Petra Nova carbon capture and storage (CCS) facility in Texas would be the largest CCS in the world, ClimateWire reports.

-

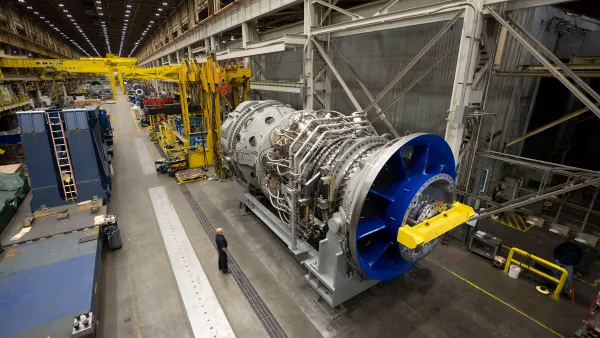

The Petra Nova facility is being built by a joint venture of NRG Energy and JX Nippon Oil & Gas Exploration at NRG’s W.S. Parish coal-fired plant southwest of Houston and is designed to capture about 90% of the carbon dioxide from a 240-MW slipstream of flue gas and sequester 1.6 million tons of greenhouse gases a year.

-

The captured CO2 would be injected in into mature oil fields in the Gulf Coast region, starting with the Hilcorp's West Ranch field in Jackson County, Texas, where the CO2 is expected to boost production from around 500 barrels a day to about 15,000 barrels a day.

Dive Insight:

CCS technology has been held up as one of the most viable options for the continued operation of coal plants in a low carbon economy. But CCS is an expensive and difficult technology.

A recent Department of Energy analysis concluded that it would cost $1.2 billion to turn the 2,094-MW Colstrip coal plant in Montana into a clean coal plant. The DOE said selling CO2 from the plant for enhanced oil recovery could generate $3 billion to $4.4 billion of revenues over 25 years based on an oil price of $106 a barrel. Current oil prices are below $50 a barrel and haven't been over $100 since mid-2014.

Aside from the Petra Nova plant, there is only one other power plant CCS project under way in the United States: Mississippi Power’s Kemper plant, which is over budget and behind schedule.

The Petra Nova facility received $300 million from NRG and from JX Nippon. NRG also won a $167 million from the DOE’s Clean Coal Power Initiative and another $23 million from DOE under a separate program. The Japan Bank for International Cooperation and Mizuho Bank Ltd. are providing loans totaling $250 million.

Petra Nova is not only being done on a smaller and cheaper scale than the Kemper project, the technology is different, as well. Petra Nova is a retrofit of an existing plant while Kemper involves building a commercial scale plant that will turn lignite into gas, separate out the CO2 and burn the resulting synthesis gas.