Dive Brief:

- Bloom Energy opened a fuel cell factory near San Francisco last week that is expected to produce 1 GW of fuel cells powered by natural gas or biogas by the end of next year, and more subsequently, according to a company spokesperson.

- The company said it made the $200 million capital investment because of the tremendous growth in demand for its fuel cells to provide resiliency during power outages and due to intense demands on the grid from extreme weather.

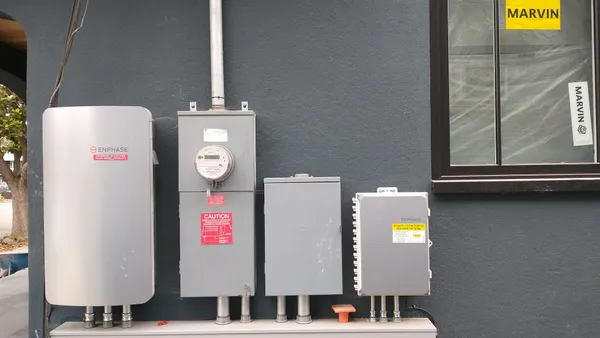

- Bloom’s solid oxide fuel cells are used in microgrids, which provide critical supply, but can also provide onsite electricity for industrial and other demands round the clock. In addition, fuel cells can be reversed so instead of producing electricity, they become electrolyzers that create hydrogen by splitting it from fossil fuels or water molecules. Hydrogen pulled from water when powered by renewables creates “green” hydrogen.

Dive Insight:

Fuel cells, which act like giant batteries, are used in microgrids that power community centers and essential services when a utility cuts off power due to the increased threat of wildfires or when power goes out due to extreme weather and other reasons. The systems can keep power flowing to critical services like fire protection and other safety agencies, water wells and electric medical devices for vulnerable people, and are much less polluting than the ubiquitous diesel generators that fire up during outages and grid emergencies.

Bloom outgrew its fuel cell factory in Sunnyvale with its 200 MW of capacity and opened a far larger one in the neighboring city of Fremont. “Demand is so strong and we need more space, we need more people, and we need more machines,” said company spokesperson Jennifer Duffourg.

Bloom, based in San Jose, California, estimates that the larger factory will create about 400 new jobs, leading to a total of 2,000 jobs when adding in its newly opened research and development center down the road and its hydrogen development facility expected to open soon.

Demand for the fuel cells is high in California because intense heat stresses the grid, particularly as the sun sets and solar power drops off the grid while demand stays high, according to state officials.

“Powering our homes and our communities has never been more important — especially as the Golden State weathers some of the most dire impacts of climate change like extreme heat and wildfire,” Gov. Gavin Newsom, D, said at the 164,000 square foot facility ribbon-cutting ceremony in Fremont last week.

“Resiliency has become a strategic imperative,” Duffourg added. Pointing to company microgrids, she added, “We are there when the grid shuts down.”

Of the 750 sites around the world with fuel cells, 520 are in California with 50 of those being microgrids, according to Duffourg.

The rise in safety power outages in California has led to a surge in diesel-powered backup generators, increasing air pollution, particularly in overburdened low-income communities.

Bloom’s new plant “appears to anchor their efforts with fuel cell technology, which is generally better than diesel-based solutions,” said Steven Moss, partner at consulting firm M.Cubed.

Last year, installations of backup systems equaled 15% of the total electrical capacity in California, and 90% of them were diesel fueled, an M.Cubed study revealed. Most are placed at data centers, government agencies, hospitals and healthcare facilities, and often near workplaces, homes and schools.

Fuel cells in contrast are powered by natural gas or biogas and produce considerably less greenhouse gas and toxic air emissions than diesel-powered microgrids or other fossil-fueled power plants because the gas in a fuel cell is not combusted but generates power via a chemical process.

Other advantages of fuel cells are that they can be built and installed quickly, and do not rely on upgraded distribution lines, said KR Sridhar, Bloom CEO. A typical nuclear reactor producing 1 GW takes eight to 10 years to build on average while Bloom expects to produce more than 1 GW of fuel cells a year, according to Sridhar.

Bloom is “agnostic” as to whether the hydrogen fuel it produces via electrolysis is derived from fossil fuels or is green, letting the customer decide, Duffourg said. But its fuel cell’s ability to use various fuels, including biogas captured from large dairy operations, or green hydrogen, puts it in a solid position to create “clean, resilient electricity” and “storable, clean hydrogen,” Bloom said.