A shortage of trained mechanics and technicians in the trucking world is nothing new. What's about to throw a wrench — or battery — into the problem: electric trucks.

"The population of experienced technicians has always been small," Rick Mihelic, director of future technologies studies at the North American Council for Freight Efficiency, told Transport Dive in an interview. "And now it's much more complicated because it's not just hiring a qualified diesel technician. You're going to have to hire somebody who's willing to also be an electric technician."

From training existing mechanics to work on two kinds of engines, to tapping a new generation of technicians attracted to newer, cleaner, software-heavy vehicles, the trucking industry is working to create a workforce ready to fix electric trucks for when they start taking over the road.

"You're developing the trucks in parallel with developing the infrastructure in parallel with developing the technicians."

Rick Mihelic

Director of future technologies studies, NACFE

The demand is even more pressing since the passage of California's Advanced Clean Trucks (ACT), which requires that by 2045, every new truck sold in the state be zero emission.

"You're developing the trucks in parallel with developing the infrastructure in parallel with developing the technicians," Mihelic said. "Everybody's on a learning curve."

Some diesel skills translate over

Fixing electric vehicles is "a very modular replacement type set up opposed to an actual fix in the field," Thomas Healy, founder and CEO of Hyliion, told Transport Dive in an interview. Instead of opening up an engine and fixing it, "you replace a module as opposed to going and fixing the module."

This is where maintenance of diesel and electric trucks have some overlap, he said. "When you look at those field replacement units, whether it be a module that needs to be replaced or inverter or motor, a lot of that is turning wrenches and connecting wires and disconnecting wires."

The chassis of an electric truck is also comparable, said Mihelic. They "have wheels and brakes, they've got cables and components, so all of those things are fundamentally similar."

Technicians who want to work on both diesel and electric trucks must be trained on safety protocols for working in high voltage environments.

Even though battery boxes aren't supposed to be opened in the field, Healy said, the risk is still present. About 400 people die in the U.S. per year from high voltage electrical injuries, according to the Centers for Disease Control and Prevention. So technicians must know how to safely de-energize the system entirely before they start working on it.

Training programs grow technicians

Rather than starting from scratch, Hyliion is working with established service networks to train technicians.

"We'd rather leverage existing networks that are already out there and put together a training program for them where we can certify technicians to also be able to work on our vehicles," said Healy.

Mihelic points to the Volvo Lights project as a bright spot. As part of its electric truck program, Volvo has partnered with the Rio Hondo College and San Bernardino Valley College to provide courses and instruction on how to work with and maintain electric vehicles.

Third-party training programs like the Clean Tech Institute and Lincoln Tech have also created certificate programs for electric vehicle repair. Mihelic expects more of these programs to develop in the near future. "This is a cash flow stream that's waiting to get tapped by these different groups," he said.

He added that recruiting should be done at the high school level too, because that generation will most likely have the skills and interest in working on software-heavy components.

Mihelic thinks electric vehicle repair could also appeal to women and people of color because the environment is different and new. He said this isn't an old, grimy workshop with calendars of scantily clad women on the wall. "It's a more sophisticated vision of being a vehicle technician than perhaps they might be familiar with, like an old garage," Mihelic said. Electric truck shops "have a different feel."

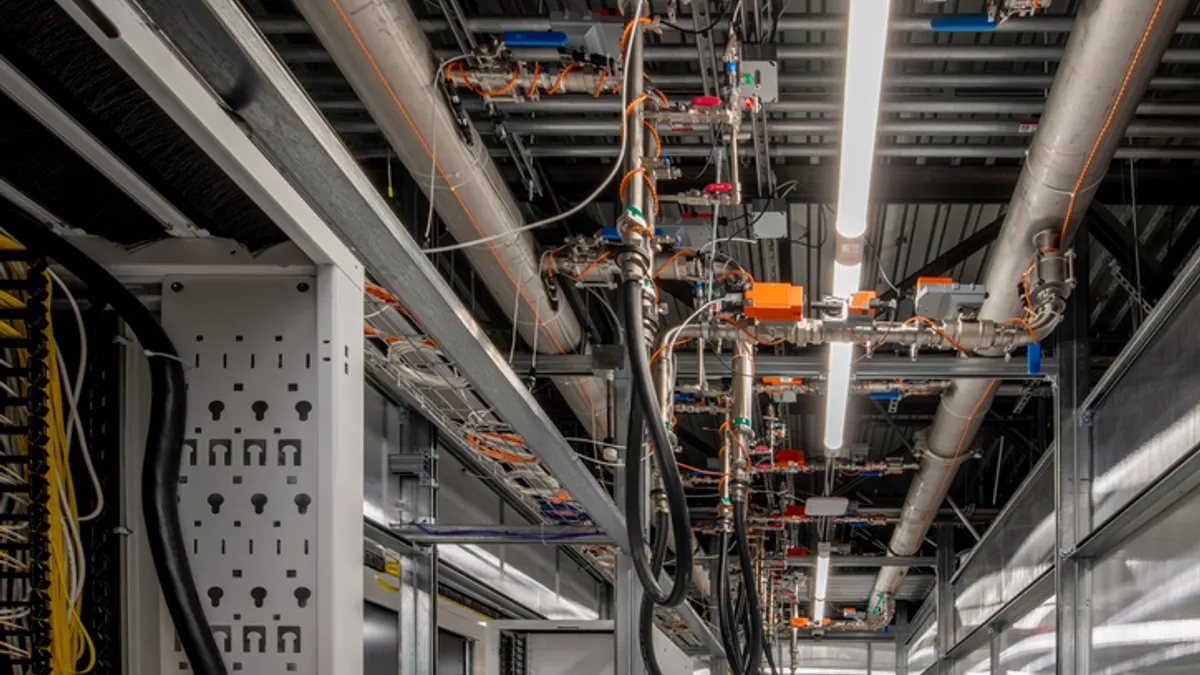

That's in part because electric trucks don't involve as much dirt and grime since they use less oil and lubricants. "Electric trucks are almost entirely clean vehicles, so you can think about a potentially a white coat type of service facility," said Healy. "One of the OEMs I talked with has a wood floor in their facility" because they don't have to worry as much about the kind of floor staining that happens in a typical garage.

"Electric trucks are almost entirely clean vehicles, so you can think about a potentially a white coat type of service facility."

Thomas Healy

Founder and CEO, Hyliion

Fleets can also take a page from Tesla's playbook and recruit electricians. "They were having trouble finding qualified people because there was really no starting point for an EV technician a few years ago," Mihelic said.

Tesla turned to the power and utility industries, Mihelic said, to find employees who understand high voltage. Tesla "[trained] them on to work on vehicles versus the other way around of training a vehicle technician to be an electrician."

A growing demand for labor

The Bureau of Labor Statistics forecasts 5% growth (as fast as average) between 2018 and 2028 for diesel service technicians and mechanics but does not break down the category further with electric technicians.

"Everybody's on a learning curve."

Rick Mihelic

Director of future technologies studies, NACFE

The exact demand for electric truck technicians depends on how the technology grows, Steven Clarke, director of corporate clean energy leadership at Ceres, told Transport Dive in an interview.

He worked on wind technology at its infancy and said the industry couldn't anticipate every kind of maintenance need because the technology was still new. The same is true for trucking.

"One thing that is clear is that there will be a significant demand for that labor force, from the chemical engineers who are conducting the R&D on new battery types through manufacturing all the way to maintenance," he said. "We see a strong and robust ecosystem and a labor force that has grown already and will only continue to grow as the demand for these vehicles increases in the short and long term."