This opinion piece is part of a series from Energy Innovation’s policy experts on advancing an affordable, resilient and clean energy system. It was written by Eric Gimon, senior fellow, Electricity Program.

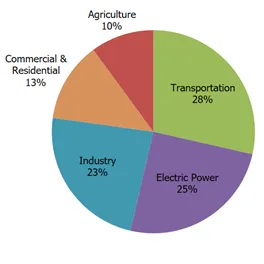

Steel, concrete, chemicals, vehicles — nearly all industry in the United States relies on fossil fuels. And all that manufacturing is directly responsible for a quarter of U.S. greenhouse gas emissions, excluding emissions from the electricity purchased by industry. We won’t have a shot at solving climate change unless we transform how we produce nearly everything in our economy. But switching industrial processes to run on clean electricity — electrification — could increase annual electricity demand by 6,000 to 10,000 terrawatt-hours. That’s more than our total national demand (4,300 TWh) and more than switching all cars to electric vehicles (2,000 TWhs). So how can we meet climate goals without breaking the grid?

Thankfully, with falling costs for renewables and technological innovation, electrifying industry can actually make the grid more reliable by adding new clean energy generation while providing flexibility services to balance out variable renewable generation and demand spikes.

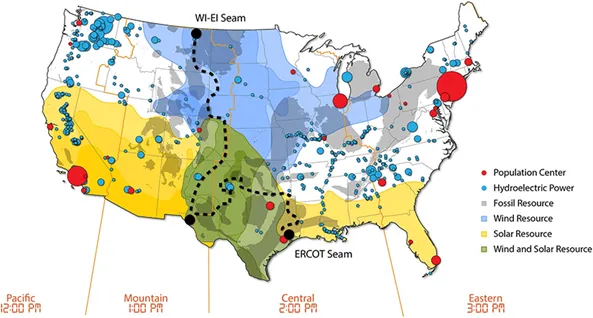

But accelerating industrial electrification requires policymakers to create rules that ensure increased electricity demand is supplied with new least-cost clean generation in rural areas with high-quality renewable resources, to incentivize co-location of industrial production and new clean energy, and to encourage collaboration between utilities and independent power producers.

While we must transform industry to cut emissions, doing so can spur massive economic growth and rural revitalization.

Dollars and cents make or break industrial electrification

The industrial sector is a large GHG emitter and a major source of local air pollutants. However, if you don’t count the cost of climate and public health damage, fossil fuels are still relatively competitive with clean electricity as a source of industrial energy and the raw materials required for industrial processes, unlike in the power sector.

What’s more, U.S. industrial energy consumers are typically not subject to financial penalties for emitting GHGs (although they tend to be regulated for local pollutants) and have access to energy from fossil fuels like natural gas at lower cost than industrial consumers in other countries.

But clean electricity can be cheaper than traditional fossil fuels for industrial consumers and could even offer a comparative advantage for commodity producers that have narrow profit margins and are thus highly sensitive to energy costs.

The most efficient way for industrial consumers to capture these savings is using new clean electricity produced at a time and place of less commercial interest than other less price-sensitive end-uses. To take advantage of these low-cost opportunities, utilities and their industrial customers should prioritize time flexibility and co-location with new clean generation.

Unlocking value: Grades of power and flexible intermediates

Bargain hunting for cost-effective industry electrification starts with grading clean power production. The Texas wind fleet’s hourly production provides a helpful example: Most raw megawatt-hours of wind production do not represent most revenue. Because wind power has zero fuel cost and it is often produced at night when demand is low, or behind congested transmission lines, it suppresses wholesale prices. Thus, most of Texas’ wind power is produced during the hours with the lowest wholesale prices. However, the nominal revenues (the sum of hourly quantity produced multiplied by market price) derived from wind power tell a different story.

In both low (2020) and high (2021 and 2022) electricity price years, on paper, the Texas wind fleet produced 30-40% of its annual revenues (excluding during Winter Storm Uri) during the highest price hours (12-14% of production) while only producing 18-29% of revenues from the 50% of production in the lowest price hours. Wind power produced during the top 20% of hours by price gets paid five to eight times more than wind power produced during the wholesale market’s bottom-priced 40% of hours.

Policymakers could unlock value by splitting clean power between industry and the rest of the grid: ensuring new industrial loads predominantly consume power below median price, thus creating a net increase in production during higher-priced hours, which are more valuable for other grid users. This netting of new production and new consumption would preferably happen near each other to preserve existing transmission capacity for the net high-grade power.

For industry, achieving this price-hunting goal requires investing in new equipment and retrofits that enables flexible electricity consumption via intermediates like thermal storage and chemical feedstocks. Technologies such as heat batteries for process heat and flexible hydrogen electrolyzers that can quickly be turned on and off, along with hydrogen storage and pipelines, can empower industry to capture cost savings from opportunistic consumption of new clean energy.

On the policy side, incentivizing these investments requires that regulators or utilities provide industry access to power at a significant price discount so long as they are flexible. One route to this goal is tariffs that avoid crude one-size-fits-all formulas for allocating overhead costs associated with wholesale power delivery and focus on exact incremental costs to the system to serve these flexible industrial loads.

Addressing policy barriers: Paving the way for clean industrial growth

To unleash the full potential of low-cost renewable power for industry, policymakers must remove barriers that impede the recognition of flexible loads in retail rate design and grid access charges by adopting three practices:

Encourage rural industrial operations to cut emissions and strengthen local economies

Locating new industrial electric loads in rural areas rich in land and renewable resources can avoid transmission bottlenecks. Moreover, transporting raw materials and products such as green hydrogen can be more straightforward than transmitting electricity. New clean power generation serving industrial loads or producing valuable feedstocks like hydrogen, ammonia, and methanol can catalyze industrial decarbonization. Local, state, and federal legislators and agencies can promote clean energy-industrial hubs with pilots and tax credits for initial projects, permitting, and public finance support for transport infrastructure, while pushing utilities and grid operators to develop sensible grid connection rules. This will cut emissions, revitalize rural communities, and widely distribute economic development benefits.

Encourage co-location of generation and industrial loads

CF Industries Holdings, Inc., the world's largest ammonia producer, and NextEra Energy Resources, LLC, the world's largest wind and solar generator, announced a zero-carbon-intensity hydrogen project at CF Industries' Verdigris Complex in Oklahoma. This joint venture shows industry co-locating new generation and new electrified industrial loads "behind-the-meter" can drive clean power growth.

Regulators and utilities can encourage industries to locate near new renewable energy sources by offering price advantages such as grid access charges proportional to transmission requirements, and by properly accounting for the local netting of supply and demand. This synergy between generation and industrial loads optimizes energy use and reduces the need for new transmission. New clean energy further promotes local economic growth and strengthens the resilience of rural communities.

Foster collaboration between utilities and industrial loads

Utilities should embrace collaboration instead of viewing generation serving behind-the-meter loads as competition. They will be challenged to meet the large capital and physical needs to sustain the additional load created by industrial electrification while achieving their net-zero commitments. Instead, flexible behind-the-meter loads that can export power to the grid during the most valuable hours can be an asset for utilities and their customers. By leveraging this synergy via partnerships with third parties and industrial park developers, utilities can drive the transition to cleaner energy and meet the needs of electrified home heating, transportation, and industrial loads more affordably and reliably. To encourage this, regulators and legislators should examine rules for direct access to the grid, open dockets to explore barriers faced by industry, and review details of the monopoly franchise (e.g., monopoly right triggers when powerlines cross any public right-of-way).

Seizing the opportunity for a sustainable future

Industrial electrification using low-cost renewable power will combat climate change, improve air quality, and revitalize rural communities. But achieving this goal requires implementing policies that recognize the value of flexible loads, facilitate rural industrial growth, and foster collaboration between utilities and industry. This transformation represents a monumental shift in our energy system, but with careful attention to existing and future barriers, and well-designed incentives, we will unlock the full potential of industrial electrification.