Bennett Resnik is a spokesperson for the U.S. Battery Machine Builders and a senior vice president, critical infrastructure, at Venn Strategies.

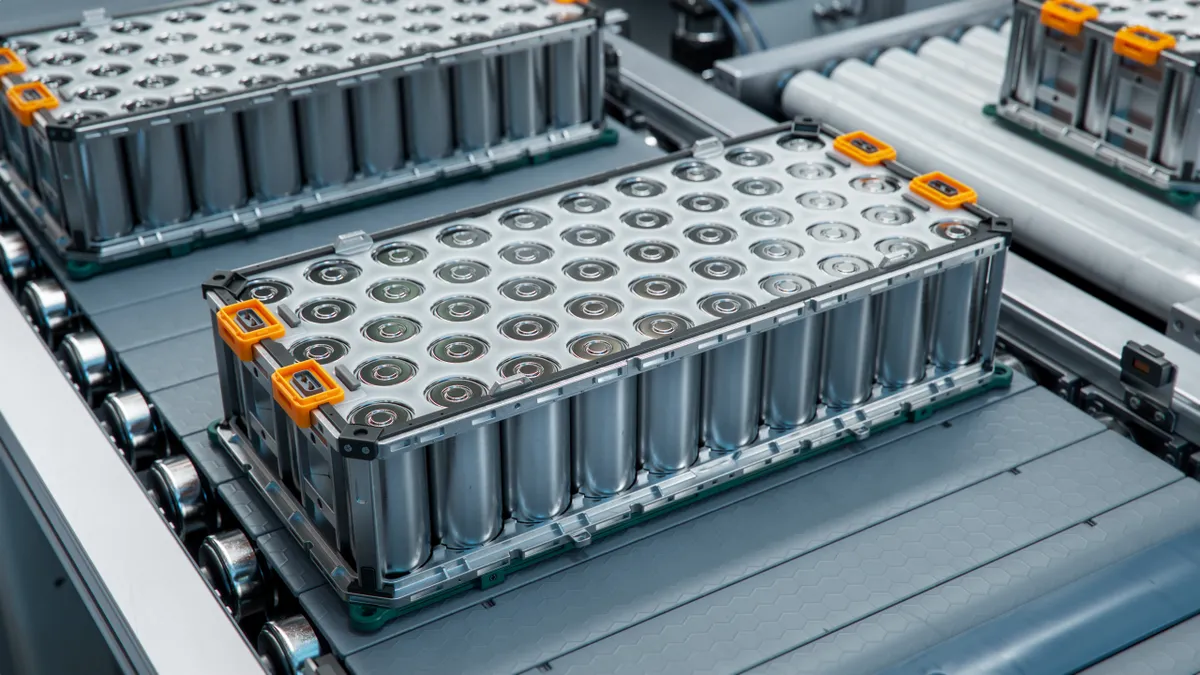

In our national push to build the battery supply chain in the U.S., policy and lawmakers have overlooked one key ingredient — machines. To ensure energy independence, national security and safeguard economic interests, the United States must bolster the domestic manufacturing of battery machines and equipment, and prioritize its sourcing in funding, financing and tax incentive programs.

Currently, like a vast majority of the battery supply chain, the machinery used to produce batteries largely comes from abroad. The February 2023 report authored by Li-Bridge, a public-private alliance working with U.S. Department of Energy national laboratories, includes “a lack of domestic suppliers of key manufacturing equipment and reliance on protective, overbooked foreign suppliers” as a key industry challenge. Establishing a robust domestic battery machines supply chain could result in an estimated “$60 billion in cumulative U.S. capital spending for equipment through 2030,” according to the Li-Bridge report.

Construction spending related to manufacturing reached $195.6 billion in 2023, according to the Census Bureau, beating the previously highest annual total on record reached in 2022 of $114.7 billion. The Bureau of Labor Statistics indicates increasing growth since 2020 in machinery manufacturing employment, yet we know these benefits have not reached the domestic battery machine manufacturing sector.

As the federal government allocates resources under the Infrastructure Investment and Jobs Act and Inflation Reduction Act to strengthen the battery and critical minerals industry, it is imperative that we ensure American-made battery machines are prioritized.

By strategically channeling federal and private sector resources towards fostering a self-reliant battery supply chain, the United States will create new jobs, put innovative technologies on factory floors across the country and forge new partnerships across industries. To that end, the Federal Consortium for Advanced Batteries, led by the departments of Energy, Defense, Commerce and State, in its National Blueprint for Lithium Batteries 2021-2030 specifies “consistent incentives and support” as part of its goal to stimulate domestic manufacturing.

The issue is front-and-center with the federal government, and public-private partnerships have formed around this high-stakes priority investment. In September, the U.S. Department of Defense announced it was awarding $30 million to the University of Texas at Dallas’ Batteries and Energy to Advance Commercialization and National Security Center to establish an energy storage systems campus, which will prioritize next-generation battery manufacturing technologies.

Now is the time to act decisively, as we build a foundation to support generations to come in an era defined by emerging energy technologies and innovation.

Domestic sourcing of battery machines and equipment is critical for several key reasons:

- National Security: Reliance on foreign-made equipment exposes the U.S. to potential disruptions due to geopolitical tensions, trade disputes and tariffs and cybersecurity threats. Domestic production mitigates this risk, ensuring access to critical technology.

- Economic Interests: Investing in domestic manufacturing creates jobs, strengthens local economies and reduces dependence on foreign materials. This creates a virtuous cycle, fostering innovation and further investment. These investments will also result in shorter lead times and more cost-efficient and accessible ongoing support to battery facilities.

- Technological Leadership: By fostering a domestic battery ecosystem, we can invest in research and development, propelling us to the forefront of battery technology and ensuring global competitiveness.

By concentrating on homegrown solutions, the U.S. can drive advancements in battery technology, setting new standards for efficiency, sustainability and reliability. This commitment to innovation will secure a leadership position in the rapidly evolving next-generation energy sector and spawn new industries, propelling the nation into a future defined by cutting-edge battery technologies.

Building a robust machine manufacturing ecosystem can be accomplished by:

- Prioritization: In all federal programs, requiring applicants to assess supply chain security and resiliency, including sourcing of domestic manufacturing equipment.

- Targeted investments: State and federal grant programs, financing and tax incentives direct to companies that invest in domestic production of battery machines and equipment.

- Research and development: Funding collaborative research partnerships among industry, academia and government to advance battery technologies.

- Skilled workforce training: Investments in educational programs to create a skilled workforce needed for the growing battery industry.

- New market entrants: Encouraging companies in adjacent industries — packaging, pulp and paper, food and beverage, pharmaceutical, etc. — to retool existing machines and invest in new technologies to meet the growing demand for U.S. battery equipment.

The U.S. is at a pivotal moment with the opportunity and paramount responsibility of promoting resilient domestic supply chains, the success of which will electrify our economy and power our way of life. To ensure the domestic battery industry can meet the moment and provide the necessary machinery to satisfy growing demand for batteries from the transportation, energy, defense and consumer electronics sectors, particular attention must be paid to not only the critical minerals used in these batteries, but the equipment used to mine, process, manufacture and recycle them.