Dive Brief:

-

Blending up to 25% hydrogen into natural gas to fire a 20 MW engine reduced emissions and produced better-than-expected efficiencies in a demonstration project by EPRI, WEC Energy Group, engine manufacturer Wärtsilä and other partners.

-

Although the engine could not achieve its maximum output on a one-quarter hydrogen blend, it did reached 95% capacity without hardware modifications. The test also produced fewer emissions of NOx than expected, while reducing carbon emissions.

-

“This was without any [hardware] adjustments to the engine whatsoever,” Andy Maxson, senior project manager at EPRI, said. “It was a very successful test and everyone is very happy.”

Dive Insight:

Mixing hydrogen with natural gas to form a bridge between today’s technology and a zero-carbon future has been a popular concept for some time. A demonstration project in the largest grid-connected, gas-fired engine to date reinforces the concept’s potential.

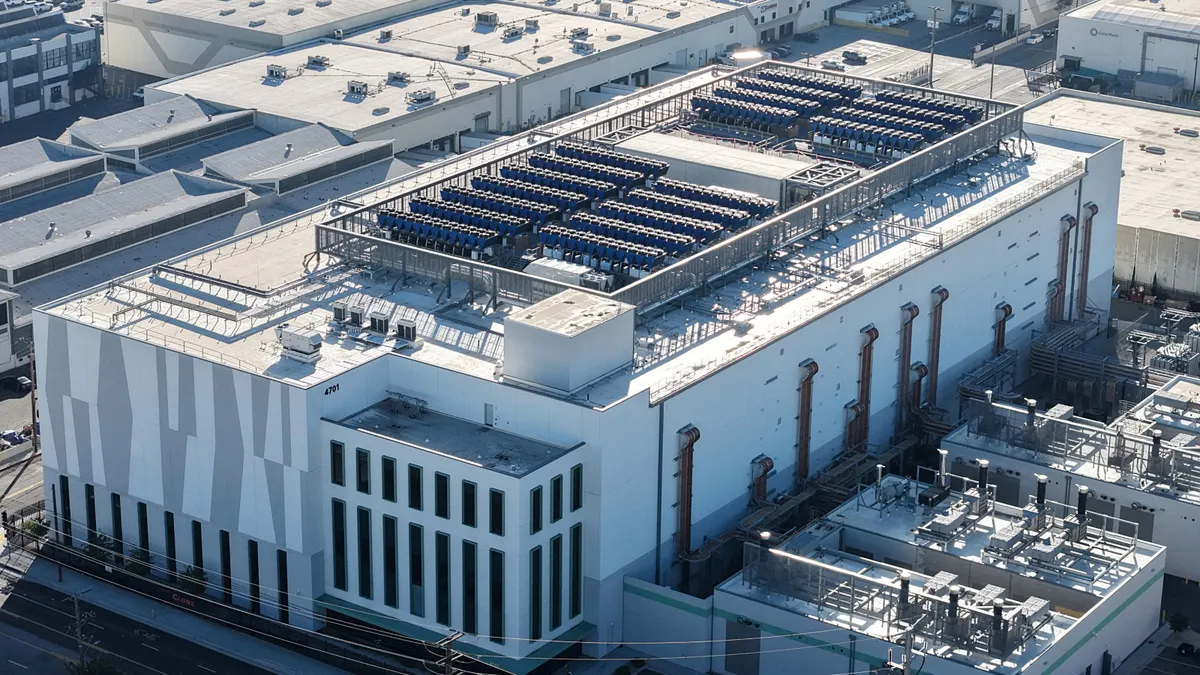

The project team ran a 20 MW engine at the Upper Michigan Energy Resource Corporation’s A.J. Mihm Generation Station on up to a quarter hydrogen with no safety issues and no detected leaks, Maxson said. Blending hydrogen into the engine’s fuel supply had negligible impacts on the engine’s performance. The hydrogen increased the plant’s efficiency by 1% when operating at half capacity thanks to the more complete combustion of the hydrogen compared to natural gas. However, the engine could only run at 95% capacity at 25% hydrogen fuel.

The test also saw carbon emissions from the engine drop 10% to 12%, while emissions of NOx remained within the site’s permit limits. Burning hydrogen produces more NOx than burning natural gas.

The engine’s hardware was not modified for the test, though the controls were altered to accommodate the hydrogen blending system. The test used green hydrogen, produced using electrolysis powered by clean energy to extract hydrogen from water, provided by Certarus. Safety specifications for the engine limited the maximum hydrogen blend to 25%.

“This is the first test of its kind, so it’s great to get a verification point that this is possible,” said Risto Paldanius, vice president of Americas for Wärtsilä.

Wärtsilä is developing an engine designed to run on 100% hydrogen that is expected to hit the market in 2025, Paldanius said. But in the interim, he said, customers have been inquiring about how the company’s engines might perform on a blended fuel. They want to ensure their purchases are “future-proof” if carbon fuels are phased out before the engine reaches the end of its useful life.

Beyond the immediate implications for the performance of hydrogen-gas blends, the test also pointed to the potential use of engines — as opposed to the larger combustion turbines—in decarbonization strategies, Maxson said. Engines are more flexible than turbines and can ramp production up or down more quickly in response to variable load, he said. Some, including the model used in the test, can also accommodate either liquid or gaseous fuels. This could allow utilities or other power generators to store a hydrogen on-site in a liquid form, such as ammonia, for use in an engine as a source of backup power.

Maxson said EPRI is interested in conducting more field tests at larger power plants and with higher percentages of hydrogen fuel.