A critical technology is needed to sustain the U.S. energy transition’s momentum, according to engineers focused on power system reliability and clean energy.

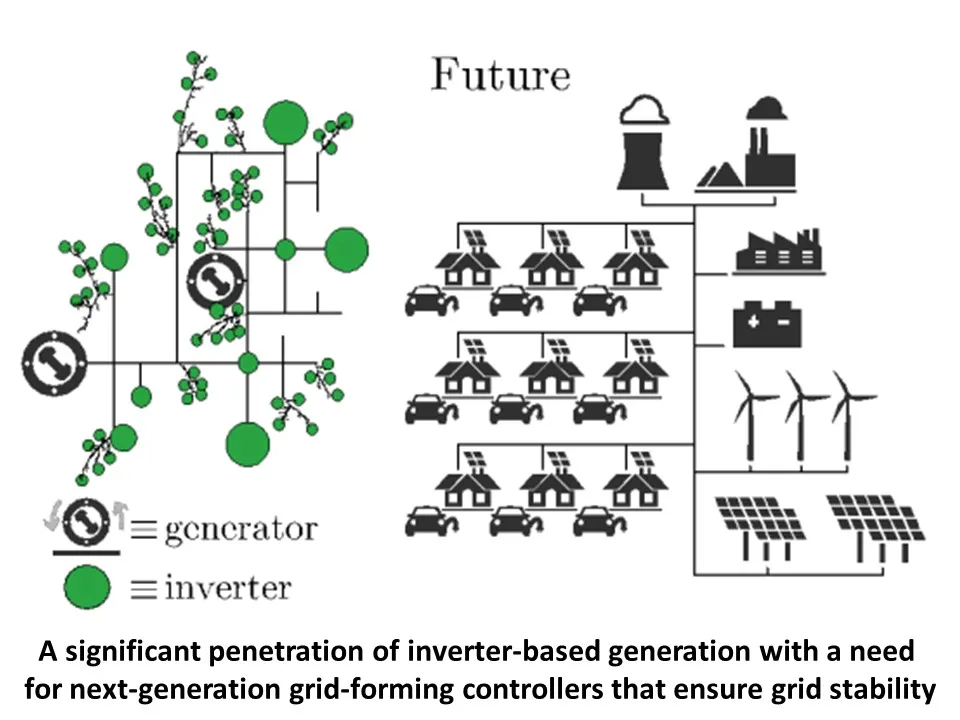

Inverters with “grid-forming” capabilities, or GFM, are needed to support the growing penetration of inverter-based resources, or IBRs, like wind and solar, according to engineers with the North American Electric Reliability Corporation, or NERC, and engineers with the Energy Systems Integration Group, or ESIG, which advocates for integrating and managing higher levels of renewables.

Inverters convert renewables-generated energy into the alternating current flowing through the U.S. transmission system.

“The power system’s heartbeat is a 60 Hertz, or cycles per second, current to which all generation on the grid must synchronize,” said NERC Senior Vice President and Chief Engineer Mark Lauby. “As long as variable renewables’ inverters synchronize their generation with that 60 Hertz heartbeat, they can deliver power into the system without concern about system faults,”

But faults causing current fluctuations go uncorrected by today’s renewables’ limiting “grid-following” inverter capabilities, making deployment of GFM with new IBRs urgent, engineers agreed.

The U.S. does not have unified comprehensive standards requiring grid following inverters, which took 20 years to develop in Europe, said Energy Systems Integration Group, or ESIG, Chief Engineer Julia Matevosyan. “And we don't have another 20 years to develop GFM standards to avoid reliability failures,” she added.

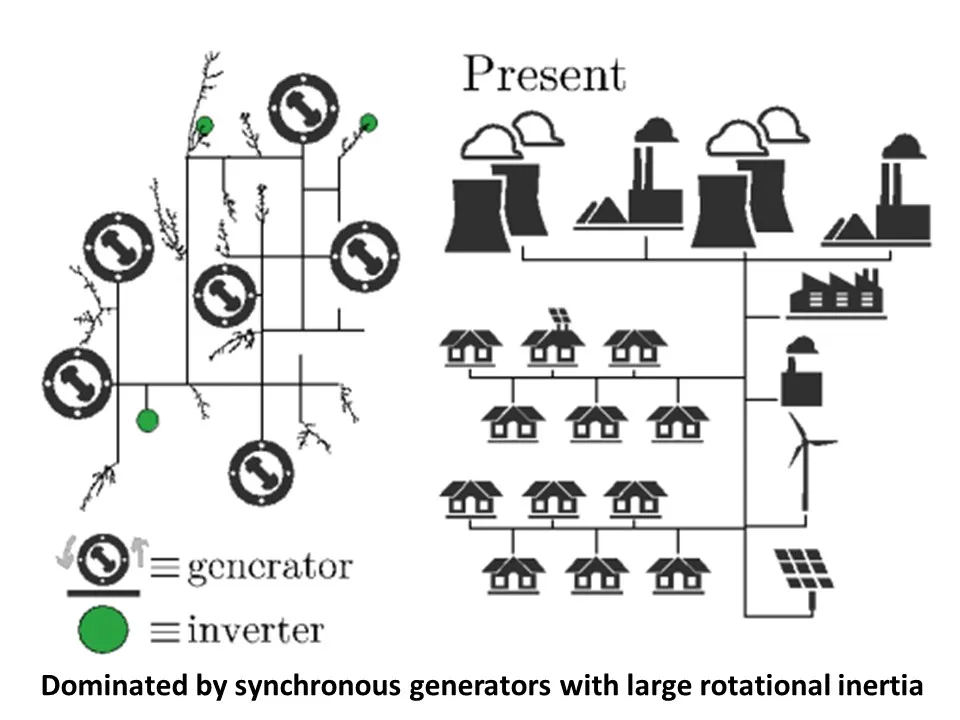

Fluctuations in the power system’s heartbeat that threaten reliability have been stabilized by traditional power plants, called synchronous machines, but they are retiring, engineers said.

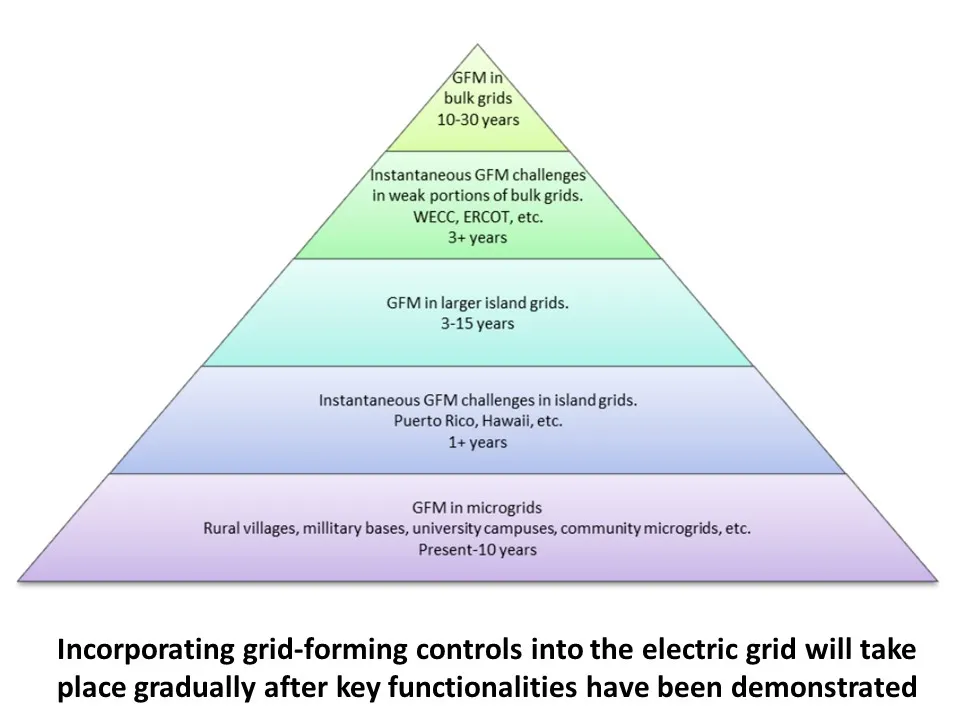

To drive GFM deployment, pilots are needed to test GFM performance, engineers agree. Standards defining GFM requirements based on the pilot results must then be set by NERC and system operators, and market incentives for protecting reliability should be provided to reward those who deploy GFMs, the engineers said.

What GFMs do

Coal, natural gas, nuclear and hydropower plants are designed to drive spinning turbines that generate electricity at the heartbeat rate of 60 hertz, according to a National Renewable Energy Laboratory November 2020 GFM Roadmap. The “spinning mass” of those synchronized machines has a momentum, called inertia, that automatically corrects frequency fluctuations, it added.

As traditional synchronous machines with rotating mass like natural gas, coal and hydropower plants, are replaced with IBRs like wind and solar projects, system inertia is reduced, “making the risk of frequency swings higher,” NREL explained. IBRs using today’s grid following inverters do not significantly address those changes, but GFM detects them and adjusts power flow to limit them, NREL added.

Without GFM, system operators can reliably integrate 30% to 75% IBRs by keeping synchronous generation online, ESIG’s Matevosyan told a Sept. 20 webinar. But keeping conventional generation online to protect reliability can lead to expensive renewables curtailments and a slower transition to IBRs, she added.

GFM can replace synchronous machines because it is “human programmed through power electronics, highly controllable and can provide very fast responses” to frequency fluctuations, Mahesh Morjaria, executive vice president, plant operational technology for utility-scale solar project developer Terabase Energy, told an RE+ renewables conference audience in September.

One key to the reliability provided by GFM is “frequency control,” to manage frequency fluctuations, the engineers said. Another is “voltage control,” to keep system voltage stable by increasing or lowering system output, they added.

GFM can also provide other system protections, called “stability services,” that detect “abnormal grid operating conditions,” and mitigate them through “disconnection of faulted parts,” NREL said.

“If the fault leads to a blackout, GFM can do a system ‘black start,’ by using IBR-supplied energy to restart generation and rebuild normal operations piece by piece,” Matevosyan said.

But including black start capabilities introduces design and operational challenges, said GridStor Senior Vice President of Engineering, Procurement, Construction and Technical Operations, Daniel Dedrick. And inverters designed for black start are 2% to 5% more expensive and require energy to drive the restart, he added.

There are other questions about the cost of introducing GFM.

GFM economics

There may be increased costs for integrating GFM into IBRs but there may also be market opportunities that offset the costs, engineers and developers said.

New inverter capabilities “do not seem to be making IBRs more expensive now,” Terabase’s Morjaria said. And as market incentives emerge, IBRs with GFM “could provide lower cost reliability services that create additional revenues because they use zero cost fuel,” he added.

GFM are “basically inverter software,” and reprogramming could make GFM-equipped batteries “marginally more expensive by a few percent of the inverter’s cost,” Matevosyan said. It will, though, be significantly more cost-effective to equip new batteries with GFM before they are deployed instead of incurring administrative, engineering, and downtime costs for upgrading after deployment, she added.

“There is also a cost for inaction,” Matevosyan continued. Without GFM deployment, “there will be continued stability challenges, continued solar and wind curtailment, and the need for costly supplemental stabilizing equipment like new transmission,” she said.

“It does not appear that the costs associated with integrating GFM will take solar, wind, and batteries out of the market,” Lauby agreed. And GFM can enable the transition away from legacy synchronous machines to IBRs, he added.

The challenge is to cost-effectively introduce IBRs with GFM to meet the growing incidences of events that threaten reliability, Lauby, Matevosyan and others agreed. NERC documented three reliability-threatening events associated with high IBR penetrations in 2022 alone, following five between 2017 and 2021.

One key solution — GFM-equipped batteries — is gaining attention.

Batteries to lead GFM deployment

The growing momentum to deploy utility-scale batteries offers a unique opportunity to take advantage of the policy-driven clean energy build-out and enable GFM at scale, engineers and analysts said.

“DOE is investing tens of millions of dollars and making GFM a huge priority and the industry needs to adopt it,” Department of Energy Director, Solar Energy Technologies Office, Becca Jones-Albertus told the September RE+ audience.

And deploying GFM in batteries “is a low-hanging fruit solution,” Matevosyan’s March 2023 ESIG paper on GFM and utility-scale batteries reported. GFM can be integrated with the over 400 GW of battery capacity in U.S. interconnection queues, enabling wind and solar growth “cheaper and faster than adding new transmission to mitigate stability issues,” she said.

Energy is immediately available in charged batteries to power reliability services, Matevosyan added in a September ESIG webinar. Solar and wind might not be producing when the energy is needed or might not be able to forego generation revenues, and services from wind might cause turbines mechanical stress, she added.

The Electric Reliability Council of Texas, or ERCOT, will finalize performance requirements for GFM-equipped batteries by the second quarter of 2024, Matevosyan reported. ERCOT will use the requirements to develop market incentives to drive adoption of GFM-equipped batteries at “weak grid” areas with high IBR penetrations, she said.

There is “a unique window of opportunity to procure, test and gain experience with GFM technology” while IBR levels are moderate and synchronous machines are still providing reliability services, Matevosyan said. And with well-designed policy and market incentives, IBRs with GFM could offset costs with revenues from new or existing stability services markets, Matevosyan added.

“It is recommended to start requiring and enabling GFM in all future Battery Energy Storage System projects,” a September NERC paper on GFM-enabled utility-scale battery systems concluded. It can be added to new battery systems “at a relatively low incremental controller and hardware cost” and “may only require controls changes,” it added.

Pilots, studies and standards

Simulations and pilots are needed to test GFM performance at scale, followed by multi-stakeholder processes to develop standards for GFM based on studies of the pilot results, NERC, ESIG and NREL agree.

NERC’s 2021 white paper and its September paper on GFM with battery systems both called for those next important steps to get beyond current limited experience with large-scale GFM penetrations, NERC’s Lauby said.

“Pilots are also needed to learn to manage sets of large, asynchronous generation while synchronous machines are retiring and load is growing,” Lauby continued. It is “very complicated engineering that could lead to using artificial intelligence, and it should be thoroughly modeled and simulated to understand the coordination and control implications,” he said.

“We need to have the same confidence with a system that has many grid following and grid forming inverters as we do with a system with synchronous machines,” Lauby added. But, Matevosyan responded, “everybody wants somebody else to adopt grid-forming capabilities first.”

“System operators need to think about operating the grid differently,” which is why DOE is funding 15 demonstrations of solar and wind projects providing grid services and reliability, DOE’s Jones-Albertus told the RE+ audience.

Following research, development and field trials of GFM, standards can be established to allow synchronous machines to be replaced completely by IBRs with GFM over the following 10 years to 30 years, NREL’s roadmap said. But for “the next decade and beyond,” the power system will have both synchronous machines and GFM-enabled IBRs, it added.

Demonstrations in California in 2016 and 2017 provided reliability services, and a small Michigan installation built in 2014 continues to stabilize a “weak grid,” Matevosyan reported. Hawaii’s Kauai Island Utility Cooperative will soon pilot GFM-enabled batteries, and Florida Power and Light will use a 2,000 MW battery deployment over the next decade to assess “the performance and benefits of GFM,” other engineers added.

“But the learning from pilots needs to come faster because wind and solar penetrations are rising and synchronous machines are retiring,” Matevosyan cautioned.