John Tombari is carbon services division manager at Battelle.

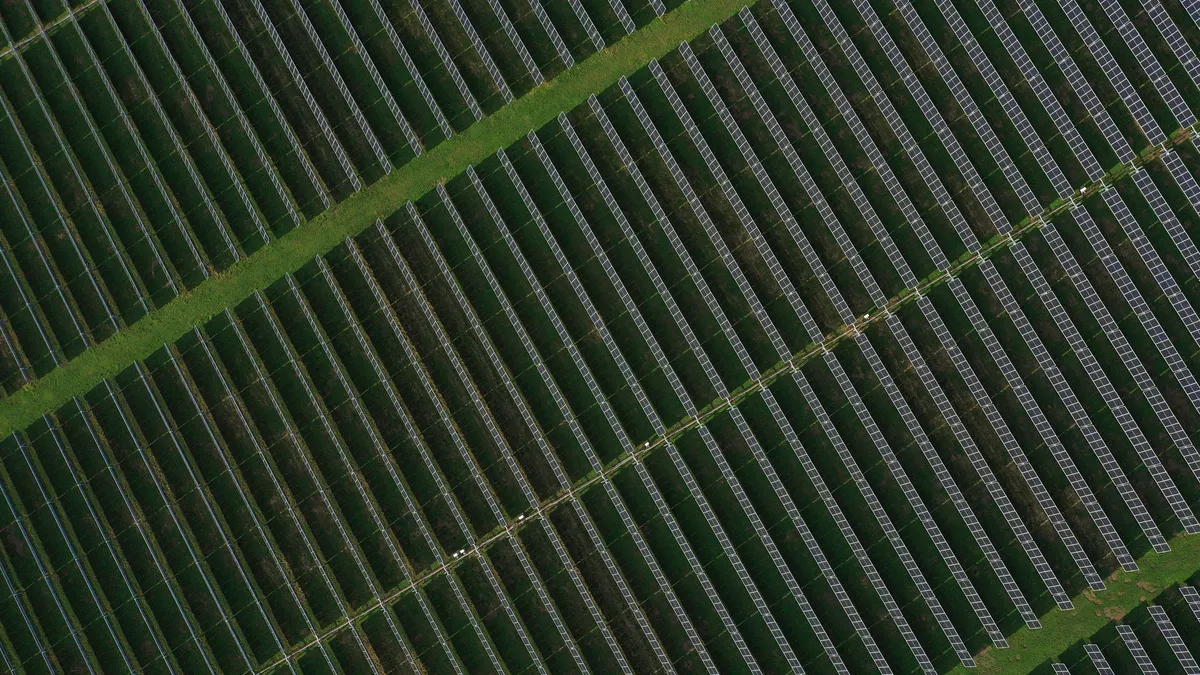

There’s no panacea for mitigating climate change. As the United States works to transition to cleaner energy systems, our ability to hold global warming to 1.5 degrees Celsius and avoid catastrophic weather impacts hinges on power producers concurrently deploying an array of decarbonization solutions to eliminate climate pollution from the sector by 2035. Carbon capture and storage, or CCS, is an essential tool in their arsenal, and it’s at a critical inflection point.

Demand for CCS is being fueled by tax incentives and the U.S. Environmental Protection Agency’s new mandate that took effect in July. The rules require that existing coal-fired and new gas-fired power plants operating more than 40% of the time and set to operate past 2039 control 90% of their carbon pollution by 2032. However, a long and laborious state and federal permit approval process is delaying the launch and operation of scores of potential carbon sequestration sites across the country.

For utility companies and power providers balking at the EPA’s eight-year timeline for compliance, this lack of progress is proof that CCS isn’t a viable solution for their timeframe. But for now, the deadline stands. Last month, the U.S. Supreme Court rejected emergency applications requesting a hold on the EPA’s 2032 carbon rule. Coal-fired and new gas-fired power plants will not be able to comply without implementing CCS, which means it’s more urgent than ever.

In their need get the ball rolling, frustrated applicants are foregoing one of the most critical actions needed for both near and long-term CCS success: drilling a sequestration test well to gather localized data. Skipping this step can lead to further delays, more costly site development and maintenance issues.

What’s holding carbon capture and storage back

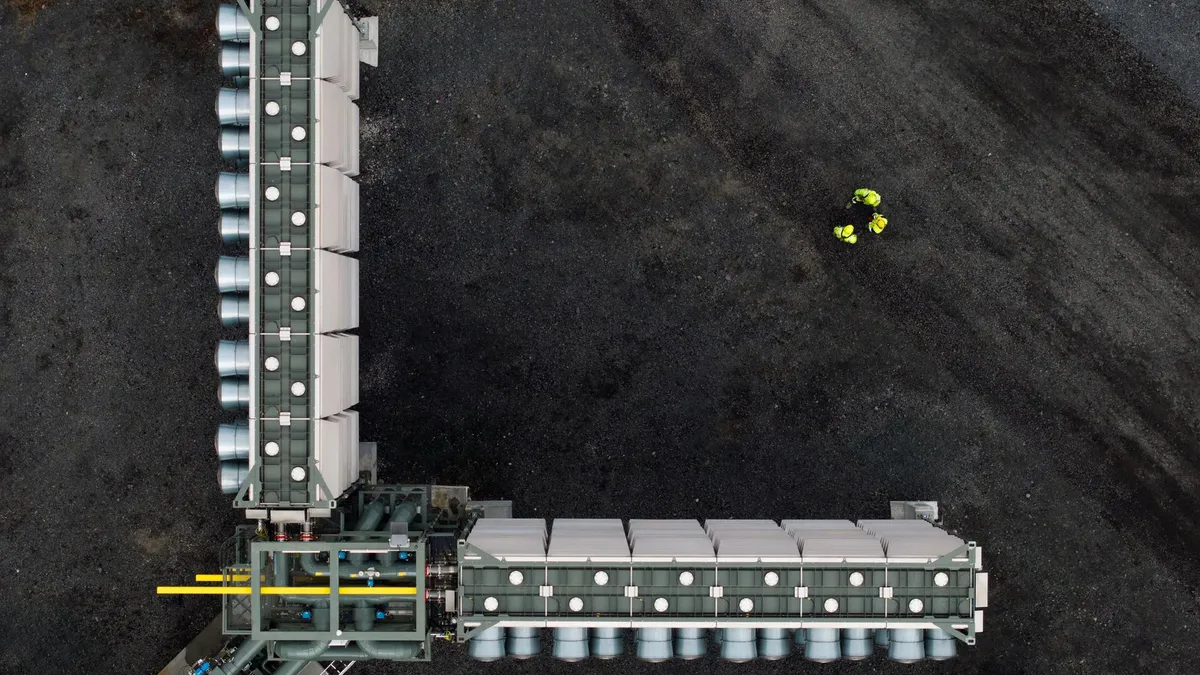

The U.S. is estimated to have the capacity to permanently store 3,000-8,600 gigatons of CO2 underground — ample room for the five gigatons emitted by the nation every year. Currently, there are 15 CCS facilities operating in the U.S. with the ability to capture 0.4% of the country’s annual CO2 emissions. An additional 121 CCS facilities are under construction or in development, which will increase the U.S.’s storage capacity seven-fold, enabling the capture of 3% of our current annual CO2 emissions.

Many more CCS sites are also on the horizon: 181 U.S. companies have identified locations with the potential to safely store CO2 and submitted permit applications to the EPA. If these locations are approved and become operational, they will add even more capacity.

But the application approval process is slow. Only eight permits have been issued in the last 13 years, and approvals are taking anywhere from two to six years. This does not bode well for fossil-fueled power plants scrambling to comply with the EPA’s carbon pollution standards while meeting skyrocketing demand for electricity. And it’s exasperating for applicants anxious to begin collecting 45Q tax credits to offset massive upfront investments in CCS.

Delayed cash flow and skepticism about the financial viability of CCS projects are also discouraging the development of new sequestration sites, which further hinders the technology’s potential. Clearer communication about what data to include in applications and a faster permit review process are needed to achieve cash flows that enable the financial incentives required for site development.

Why it’s vital to drill for the right data

The EPA is not the only entity with the power to expedite approvals. Applicants can prevent delays and avoid future operational headaches by committing to data-driven rigor from the outset.

The quality, amount and locational specificity of the data submitted with every CCS site permit application is not only crucial for proper processing but also for site design and overall risk reduction. Sequestration wells for CCS have unique design specifications and regulatory requirements that make them vastly different from the standard wells for oil and gas extraction.

However, many site applicants submit basic regional geologic data supplemented with conventional offset well data, rather than drill a sequestration well and collect information specific to their proposed site. Using readily available, location-agnostic data is less expensive but will likely cost more time and money in the long run. Applications that lack sufficiently localized data run the risk of failing to receive the permit on their first application, and those that manage to get approved are at higher risk of unforeseen issues and risks as they build their site and begin operations and monitoring.

Designing a site and monitoring system built for the long haul

The subsurface is a complex and dynamic environment, which is why a greater understanding of a site’s characteristics translates to a more successful CCS project. Utilities and power companies need three kinds of key data to reliably confirm the viability of their proposed carbon sequestration site:

- Capacity: How much space is available to store CO2 below the drilling site?

- Injectivity: How easy will it be to inject CO2 into the space?

- Containment: Will the injected CO2 remain in the permitted space?

This data is also critical for designing a safe and efficient CCS site and developing a sustainable long-term management strategy. It can determine the number of wells needed, which size compressors should be used and the mix of monitoring technologies that will work best. It also helps model the projected shape and evolution of the injected CO2 plume over time. Information collected from a test drill can help confirm there are no faults, fractures or other pathways that would allow CO2 to migrate out of the storage space.

Utilizing precise data in tandem with a monitoring tool for stored CO2 can help site operators reduce their costs and avoid encountering carbon storage risks. It will also equip them with the information they need to proactively respond to the intensifying regulatory reporting requirements of the EPA and the California Air Resource Board. And with a multi-physics monitoring platform, operators can collect frequent measurements rather than relying on the sporadic data gleaned from expensive geological surveys conducted every five years.

Investing now will set CCS up for maximum success

CCS is not a one-size-fits-all solution, but it is an important mitigation option when deployed correctly. And for utilities, it’s essential to their ability to comply with the EPA’s near-term emissions mandates while continuing to operate existing plants. Fully transitioning to clean energy will take our nation decades, and coal-fired and new gas-fired power plants only have eight years to meet a CO2 emission standard equal to installing a CCS system and running it at 90% efficiency. This beneficial technology can only reach its full potential if properly designed, operated and monitored CCS sites are up and running as soon as possible. And that begins (and ends) with the right data.