Measures to control the spread of coronavirus in China could significantly affect the country's storage and solar sectors, according to analysts — but the impact on the United States' power sector is mixed.

Eight provinces in China announced work stoppages because of the coronavirus, including the Jiangsu province, which houses several solar manufacturing campuses, according to notes from ROTH Capital Senior Research Analyst Philip Shen, leading to possible shortages that could cause solar ecosystem pricing to go up in the near term. Meanwhile, analysts at Wood Mackenzie estimate that the country's battery storage production capacity could drop by 10% — or 26 GWh — of earlier forecasts for 2020.

The impacts of the virus on China's power sector depend on how long the outbreak continues and how far it spreads, Josiah Neeley, senior fellow of energy policy at the R Street Institute, told Utility Dive. If it continues for more than a few weeks or spreads to more of China, it could have a significant impact on Chinese economic output across the board. But a major disruption in the U.S. power sector isn't likely, since electricity generation comes from either domestic or non-Chinese sources, like coal, nuclear, natural gas and renewable energy.

A 10% reduction in battery capacity is unlikely to lead to a major disruption unless the virus spreads and causes serious outbreaks in other countries, Neeley said.

"Right now, there are various ways that [that reduction] could be made up: either sourcing from other countries… or later, after the outbreak is over, ramping up production — or just eating the delays," he said.

'This is going to be a very big deal'

A 10% reduction in China's forecast lithium-ion battery storage production capacity would bring its expected 2020 output to 237 GWh, according to Wood Mackenzie's analysis. However, that figure could drop if delays persist.

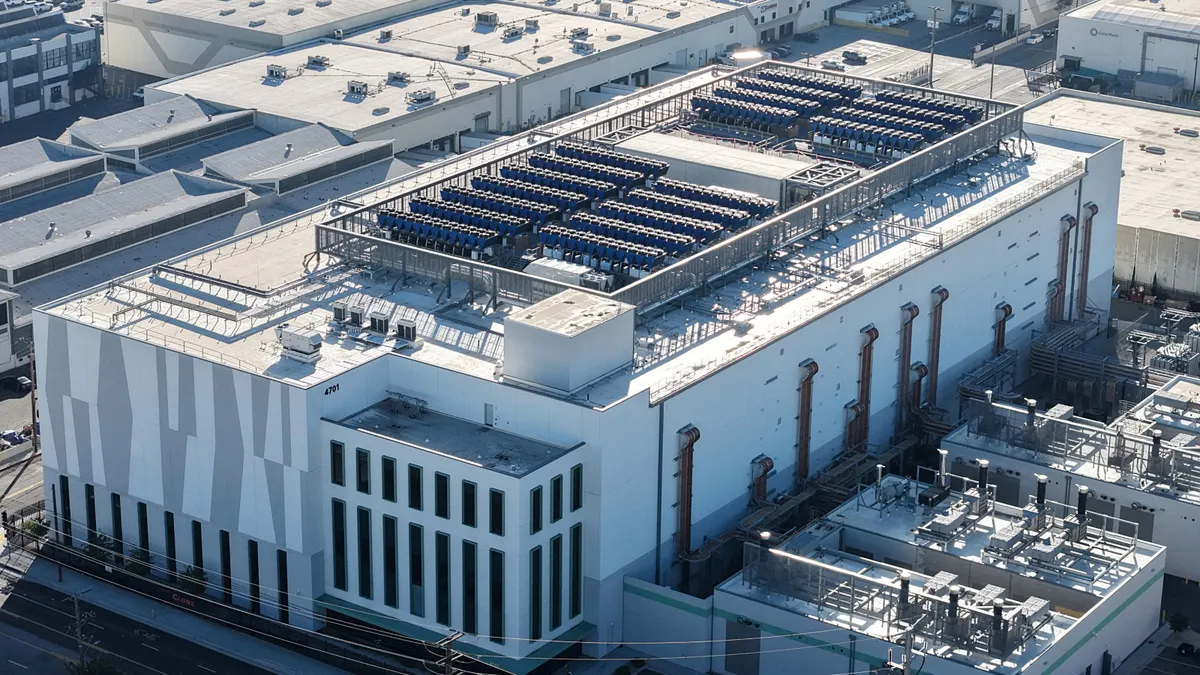

Restrictions on labor movement will impact auto manufacturing in the Hubei province and heavy manufacturing industries in the Shandong, Jiangsu, Zhejiang, Fujian, Anhui and Guangdong provinces, senior research analyst Le Xu said in a press release — regions that were collectively expected to contribute 162 GWh of battery cell production this year. The government has canceled domestic flights, trains and public transportation to affected areas, and coupled with the extension of the Chinese New Year holiday, heavy manufacturing industries that depend on laborers moving from one area to the other — like batteries — could be impacted, Daniel Finn-Foley, head of energy storage at Wood Mackenzie, told Utility Dive.

"This is going to be a very big deal," he said.

The reduction in capacity comes at a interesting time for the U.S., according to Finn-Foley. In 2018, much of the supply of batteries from South Korean original equipment manufacturers was directed into the South Korean market due to incentives there, which led to U.S. developers turning to Chinese vendors and "getting more comfortable with them" in 2019, he said.

"So now we're coming from a supply constraint in South Korea to a supply constraint in China," and a significant supply shortage could affect prices, and that will trickle down to the market.

The timing of the constraint is also significant, given the U.S. Department of Energy's recent Energy Storage Grand Challenge, which focuses in part on building out a domestic supply chain for storage technologies, Finn-Foley said. As the international supply chain begins to look riskier, "that could be an opportunity for a non-lithium ion technology provider to further make their case that their technologies are worth investing in from a domestic economic standpoint, and also from a supply chain exposure standpoint."

Solar sector sheltered by tariffs

On the solar front, the industry will likely experience supply chain disruption and constraints of glass, aluminum frames and metallurgical-grade silicon, but these will be relieved in the near term, according to ROTH Capital's Shen.

"This is likely why solar stocks with China exposure continued to work last week on the expectation that work stoppages would not be extended. That said, we are not convinced the disruption is even close to being over," he wrote on Feb. 10.

The sector could be impacted at every step from manufacturing to workforce, suppliers and logistics, and shipping, Ravi Manghani, head of solar at Wood Mackenzie, told Utility Dive. Delays in factories reopening would push back actual production and even after workers come back, they either go through a quarantine program or are kept in constant observation, which could impact operations and shipping.

But the U.S. isn't the market that would see the most impact, Manghani said, since its reliance on Chinese modules has dropped considerably since the introduction of tariffs. A lot of the modules used in U.S. projects come from Chinese vendors in South East Asian countries, many of which rely on raw materials from China, so there could be a ripple effects — "but at least in terms of immediate impact, we do think the U.S., because of the tariffs, is slightly protected from any sort of immediate and long-term impacts," he said.

If the outbreak were to be sufficiently contained by the end of February — the best-case scenario — prices of solar cells and modules would not drop in the first half of 2020, according to analysis from Xiaojing Sun, senior research analyst, solar systems and technologies, with Wood Mackenzie. But in the worst-case scenario, where the outbreak continues for months, U.S. module prices are projected to rise by 5% in the first half of the year and remain high in the third quarter of 2020 as well.